The new LiFePO4 battery bank has been installed!

In the space of two 4D batteries, which contained a total of about 400ah of energy, 840ah of LiFePO4 power now sit. That’s twice as much, but wait there’s more…Of the 840 ah, over 700 are usable without long term damaging effects to the batteries, verses a mere 200 for the Pb-acid. So a 350% increase in the house bank and in the same space!

Before I outline the process, let me say that while you can save a large portion of the cost of commercially available LiFePO4 “drop-in” replacement batteries, this is not for the faint of heart. I’ve had many setbacks along the way, which I’ll share on the chance that my solutions may be helpful to someone.

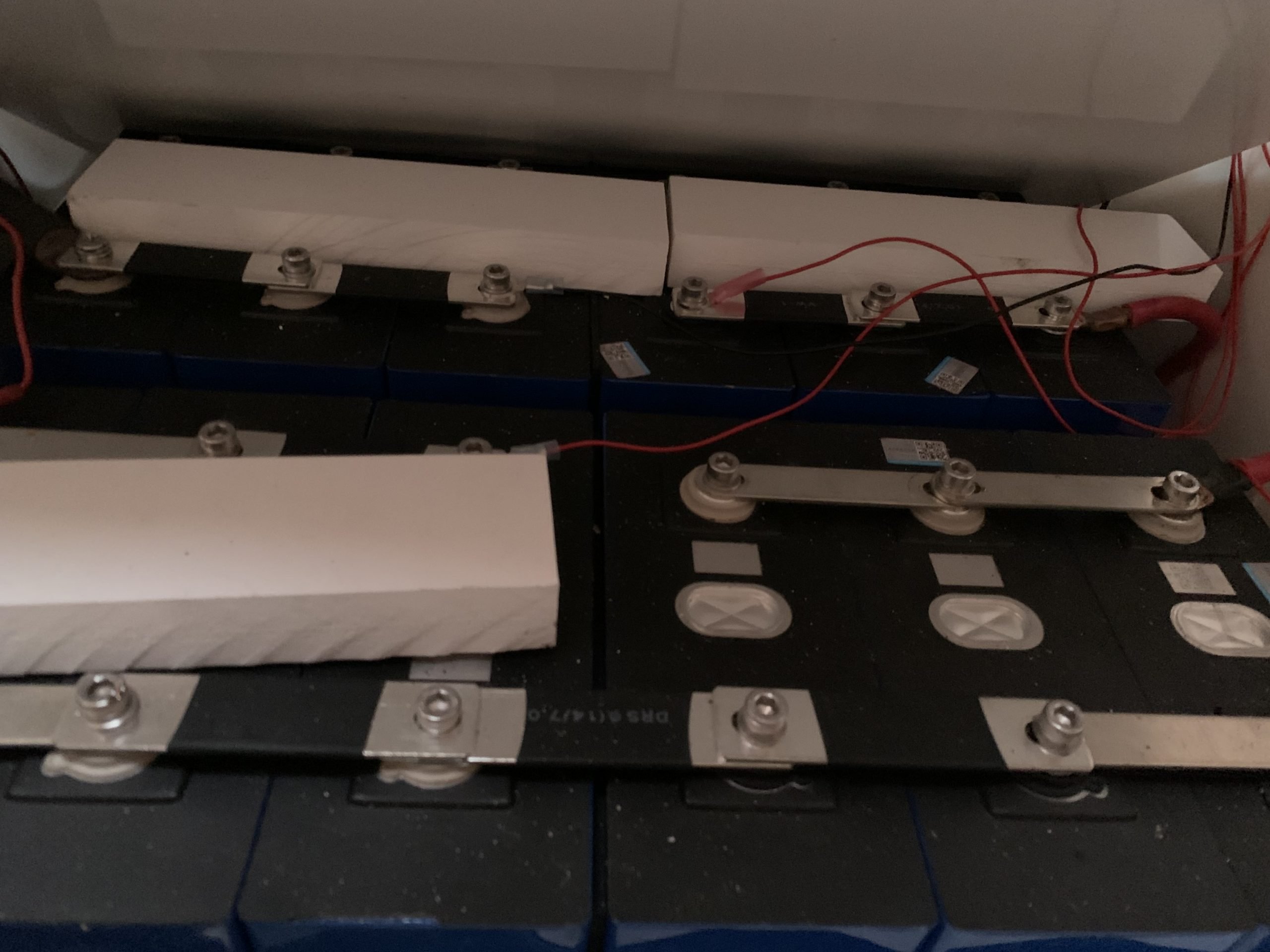

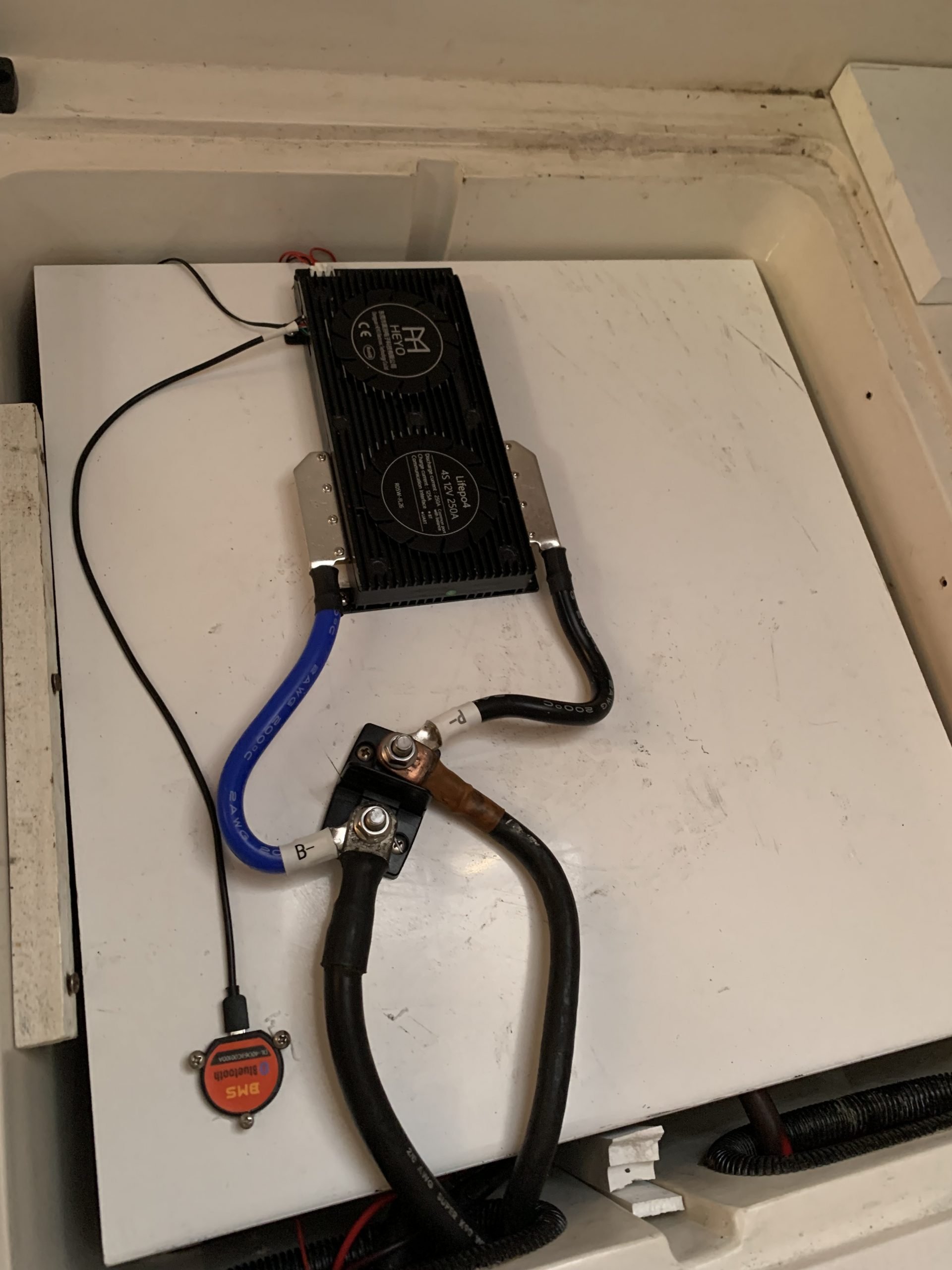

First and foremost was fitting the pack into the space that the two house 4D batteries came out of. In my case, the battery box is molded into the fiberglass. The battery box shares a space with one water tank. I foresaw an issue because the battery pack was physically smaller than what was replaced, As the boat pitches and yaws, the batteries would be able to move, which could loosen the connections or even throw them with such force as to break molded compartment. I thought I would make spacers. Great idea, proved nearly impossible due to the radiuses around the corners and the taper of the compartment. Too much time was consumed fitting the spacers and I was still not satisfied with the job. I’ve ordered two molded 4D sized battery cases designed for DIY battery packs. Each will hold 6 cells in a 3P2S (3-parallel, 2-series) configuration for 2 six volt modules (which will be connected in series). The BMS will be fitted outside the cases, though they will have external plugs for the balance wires.

The next issue was how to deal with the starter load and the alternator. Though the starter load can be handled by this pack, the high current rush of a starter motor does shorten the life of a LiFePo4 pack. The low resistance of the pack could easily overheat and burnout the alternator if it were called on to charge a depleted pack. One additional issue is my monitoring system in winter. The Li pack would happily power it down to -30 C (-22 F). degrees, but they should not be charged below -5 C, (23 F). It could deplete the pack over a cold winter. A separate AGM battery seemed to me to be the best solution. I only have to segregate the windless, starter, alternator, and monitoring system from the house bank. Add an additional shutoff and a means of charging the lead battery via shore power.

Another design issue is what settings to use. Li banks do not like what is known as “float” or “equalize” charging. Equalizing was already turned off for the old AGM bank. While float charge could be disabled as well, doing that would mean that the solar power would not flow to the house load unless the batteries happened to be charging. And it was disabled in the sample LIFePO4 profile from Morningstar. They suggested charging to 14.2 volts for 30 minutes (daily) with no float. This means that the charger will provide current for 30 minutes after 14.2 volts has been reached. This is slightly lower than the 14.6 volts (3.65 volts/cell * 4 cells) that the manufacturer recommends, but should achieve about a 90% state of charge. Good for the batteries, except that it fails to consider that there is always a drain from the monitoring system.

If I want the solar panels to provide power to running systems, I needed the float cycle. In order for it to not charge the batteries (which they don’t like), the float voltage had to be just below the charge voltage. Based on experimentation, it seems that a absorption charge of 13.8 volts for 30 minutes, followed by a float charge of 13.6 volts achieves my goal of replenishing the battery from the night usage, then when the charging is stopped, the float provides power to the DC bus (the battery voltage will drop slightly once charging is halted). The batteries will remain around a 90% SOC until the float charge can no longer provide enough current for the load. To this I added a monthly equalize charge to 14.2 volts for 30 minutes so once a month the batteries will be fully charged. This is optional.

Project cost:

- 12 LiFePO4 280 AH cells $1425

- 250 amp BMS 152

- extra busbars 21

- cases 289

- Hardware 55

- Battery cables 125

Total $2067 includes delivery and sales tax.